Commitment to Responsible Peat Use

For over 200 years peat has been inextricably linked with many Scotch Whiskies. Used during the malting process to impart a distinctive ‘peatiness’ to malted barley, this unique organic material is an essential component in the production of some of the most famous Scotch Whiskies in the world. Highly recognisable, peat smoke is one of the most memorable aromas and flavours in Scotch Whisky

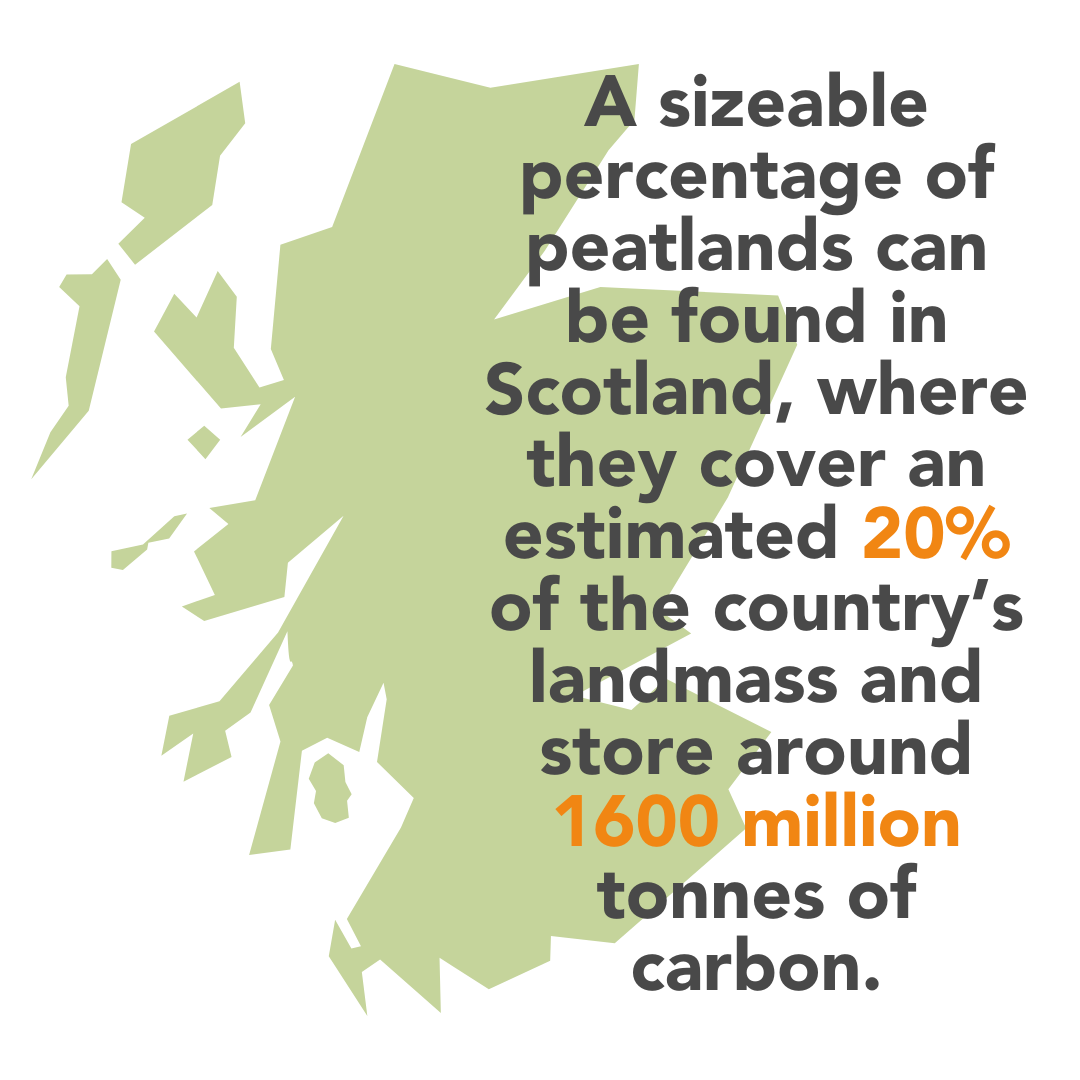

Beyond peat’s distinctive flavour in whisky, peatlands are some of the most valuable ecosystems on Earth.

DID YOU KNOW?

Aside being found in all peated single malt Scotch Whisky, many blended Scotch whiskies (which makes up over 85% of the market) also include a peated influence.

In addition to locking in carbon, healthy peatlands can support biodiversity and contribute to local water quality.

Despite this importance, roughly 80% of Scotland’s peatlands are degraded. The reasons for degradation range from the drainage of peatlands for agriculture and commercial forestry, grazing management, the expansion of energy infrastructure like windfarms, and extraction for industry use and home heating.

In their degraded state, peatlands not only emit carbon but can increase flood risk, harm biodiversity, and release sediment into waterways.

Most peat extracted annually for use in Scotch Whisky production is sourced from independent suppliers by third-party maltsters. Malting companies produce the peated malt that is sold to distillers, but a select number of Scotch Whisky producers maintain their own malting facilities and their own extraction site. Overall, there are nine facilities which produce peated malt for the industry, each using a small number of peat sources.

DID YOU KNOW?

It has been estimated by the Maltsters Association of Great Britain (MAGB) that 8,000 tonnes of peat was used in the production of Scotch Whisky in 2023, to produce 64,000 tonnes of peated malt.

Compared to the overall quantities of peat displaced annually in Scotland by peat-dependent industries such as horticulture, the amount required to produce Scotch Whisky each year is very small. The industry readily acknowledges that responsibly using the peat we do extract is a fundamental aspect of our environmental obligations.

No peat use is negligible in terms of impact on the environment, and it must be guided by principles of responsible land management, efficiency, and a comprehensive programme of restoration and stewardship.

Commitment to Responsible Peat Use

Against this backdrop, the SWA produced the Commitment to Responsible Peat Use (CRPU) in 2023. The CRPU is:

✅ High-level

✅ Peer reviewed

✅ A sustainable future for peat in the Scotch Whisky industry

The activity within covers three key areas:

RESPONSIBLE EXTRACTION

OPTIMISATION & EFFICIENCY

PEATLAND RESTORATION & STEWARDSHIP

All must be addressed to ensure we are responsible users of this unique resource.

In 2025, the commitment was refreshed by the SWA’s Peat Supply Chain Working Group, a group of key peat-dependent Scotch Whisky producers, industry scientists from the Scotch Whisky Research Institute (SWRI) and representatives from the Maltsters’ Association of Great Britain (MAGB). The report will continue to be biennially reviewed and reissued to ensure that we reflect the current priorities in peatland protection.

RESPONSIBLE EXTRACTION

The SWA will require the highest environmental standards of care to be applied to its members’ extraction sites as is determined by expert advice and their site-specific restoration plans. We will work with independent experts to develop a best practice standard in peat extraction for the industry

Following the publication of the National Planning Framework 4 (NPF4) by the Scottish Government in 2023, new protections have been introduced for Scotland’s peatlands. The SWA welcomes the increased protections which are provided through NPF4, and we will do all we can to support the ongoing regulation of peat extraction. The CRPU commits us to take the initiative to not only meet our legal obligations as peat consumers and harvesters, but to exceed them. We will leverage our influence to work alongside member companies and supply chain partners to ensure higher standards across the peat supply chain.

We’re supporting Scotch Whisky distillers, maltsters, and partners with simple, accessible expert information on best practice in peat extraction and information on extending permissions, with clarity on requirements from Scottish Government and guidance from leading authorities such as NatureScot’s Peatland Action.

We’re also facilitating site visits, enabling site managers to share key learnings with other stakeholders, demonstrate process towards implementation of their restoration plans, and hold themselves to account to meet the required standards of care.

Minimising impact

The methods of peat extraction used in sites that provide for the Scotch Whisky industry are varied, from ‘deep-dug’ methods with heavy machinery for full depth extraction sites, tractor-pulled ‘sausage’ or ‘screw’ extruders to other, often smaller-scale sites which still employ traditional cutting methods. The potential impacts these different methods have on the surface flora and the peat are also varied; each with advantages and disadvantages.

The SWA is publishing guidance for members on how to assess extraction methods, with optimal draining techniques, run-off control, vegetation placement and other examples of best practice to be considered and employed where possible. All effort must be made to maximise a site’s restoration potential by minimising the effect of extraction methods.

BEYOND THE EXTRACTION SITE

Alongside seeking to understand best practice and promoting the use of new, less invasive extraction methods, the SWA, MAGB and the Scotch Whisky Research Institute (SWRI) have begun to broaden our horizons to assess the viability of an alternative solution to the sourcing of peat.

Across Scotland, important infrastructural and energy projects have the potential to displace up to hundreds of thousands of tonnes of peat a year. Even though companies hold obligations to ensure that as much of this peat as possible is used in the service of a restoration project, a significant quantity remains displaced. With the support of the SWA and MAGB, SWRI are spearheading a study aimed at assessing the viability of taking peat displaced by construction projects in other industries for the purposes of making peated malt. This work is being undertaken alongside partners in the energy industry, with industrial trials now taking place in selected maltsters across Scotland. A second phase of this trial will involve a selection of SWA distillers creating a peated whisky using the peated malt produced.

Location and moisture content play a critical role in establishing the flavour profile of a peated Scotch Whisky and these variations pose a significant challenge to the widespread adoption of displaced peat over traditionally extracted peat from a consistent source.

Should trials produce a Scotch Whisky that is within acceptable flavour parameters, then assessment will begin on the long-term logistics of using displaced peat as a standard source of peat within the Scotch Whisky industry.

OPTIMISATION & EFFICIENCY

The SWA will work closely with SWRI and MAGB to support research to increase the efficiency of the process to make peated malt to reduce emissions and optimise peat use.

An important element of using peat responsibly is optimising the peat we harvest. Maximising the efficiency of the malting process helps minimise overall emissions produced from burning peat and further reduce the amount required by the industry.

To achieve this, the SWA works closely with MAGB’s Kiln Efficiency Working Group and SWRI’s Peat Research Group to identify ways to increase efficiency and reduce emissions associated with peat use in malting operations.

The priorities of SWRI’s Peat Research Group include:

- Increasing our understanding of congeners (chemical components) responsible for peaty flavours to allow better monitoring of peat within the malting process

- Improving efficiency in the kilning process by understanding the parameters required to optimise generation of peat smoke and its adhesion to malt

- Decreasing the losses of peat congeners in the whisky making process

- Assessing novel ways to change the kilning process as it’s defined within the Technical File for Scotch Whisky

Developments in the Malting Sector

Critical to the delivery of the industry’s commitment towards improving malting efficiency is close collaboration with the malting sector. In recognition of our combined role in achieving a sustainable future for the industry’s peat use, MAGB, the SWA and SWRI work in tandem with the growing network of peat work groups to drive change in the sector.

All companies within MAGB which produce peated malt are seeking ways to optimise the efficiency of burning peat, with many already carrying out trials. Considerable investment is underway across the sector and includes the construction of new kilns which innovate on existing designs by adding a self-contained ‘peat box,’ which helps increase efficiency. Similarly, some sites have installed new ducting to traditional kilns which improves both control of kilning activity and smoke flow to the malted barley.

PEATLAND RESTORATION & STEWARDSHIP

The SWA will promote peatland restoration efforts across the industry by strengthening the relationships between member companies and the bodies spearheading restoration. As industry leaders, we will drive an increase in peatland restoration undertaken by our membership.

The Scottish Government has committed to invest £250m to restore 250,000 hectares of degraded peatland by 2030. This multi-annual investment will deliver peatland restoration activities through a number of partners in public, private and third sectors, part of which is co-ordinated by NatureScot.

Beyond this, many distillers are already engaged in the active restoration of peatland that goes beyond their potential obligations relating to their peat extraction sites. In the past number of years, the industry has conducted many such restoration projects – some of which can be learned about below – with many more in various stages of planning.

The SWA itself has now begun to increase its own monetary support towards the delivery of peatland restoration. Building on previous activity, which included providing funding to support the work of the Ugie Peatland Partnership in the North East and sponsoring the IUCN Peatlands Conference, we’ll continue to engage with leading NGOs and government bodies enmeshed in peatland restoration through regular review and discussions on ongoing restoration projects, and the potential for collaboration.

This will not only ensure that the Scotch Whisky industry is aligned with those most knowledgeable of Scotland’s peatlands, but that the SWA can offer effective guidance to our expanding membership on how to best engage in peatland restoration in years to come.

The SWA strongly supports the work of its members to forge a path towards responsible extraction activity at their peat extraction sites as we seek to define best practice in peat extraction for the industry at large.

One way in which the SWA is seeking to the works and aim of member companies is by working with the Scottish Environment, Food, Agriculture Research Institutions (SEFARI) to develop a bespoke research opportunity that will inform the SWA’s understanding of best practice in peat extraction whilst aligning with the UN’s Sustainability Development Goals as well as the Scottish Government’s National Outcomes.

Supported by the SWA, the Scottish Government and our supply chain partners, a small research team will set out in 2025 to analyse the peat extraction methods employed in Scotland and beyond in terms of cost, complexity, scale and their impact on the environment. The SWA is interested in learning which of these methods cause minimal harm to the extracted peatland and enable the most effective restoration following the end of the extraction lifespan of the site whilst taking into account that the nature of some peat extraction sites can make certain restoration methods unviable. The research team will also review the range of peatland restoration methods used across the globe to determine which are best employed on extracted peatland. Taking all of these findings into account, the partnership will propose an outline of best practice in peat extraction for the Scotch Whisky industry which the SWA is committed to adopting and promoting to its membership and the wider supply chain.

What’s next?

With the support of independent peatland experts, the SWA is committed to defining what ‘best practice in peat extraction’ means to our industry by the end of 2025. In defining best practice, we aim to ensure that peat is extracted in a manner that is as sustainable as possible: dealing minimal harm to the peatland surface; limiting emissions from degraded tracts of peatland; and leaving an environment that can be most effectively restored through an ambitious restoration plan.

This will be followed by a framework for best practice in peat extraction with additional perspective specific to the Scotch Whisky industry. The final publication – expected in Q4 2025 – will account for the variety of extraction sites used by the Scotch Whisky industry.

Additionally, the SWA is developing a toolkit for peatland restoration, outlining available support and funding. It will be created with advice from consulting peatland experts and will include access to a forum where SWA members can communicate learnings and be informed of successful projects. The toolkit will be aimed at smaller distillers interested in engaging in peatland restoration and will be published in 2026.

In 2024, the SWA became founding members of an exploratory group of Scottish businesses seeking to create a peatland restoration fund aimed at helping SMEs to contribute financially to peatland restoration. More details of this peatland restoration fund will be shared as the structure of the fund is developed.